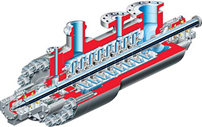

The LDTN condensate pump is a vertical multi-stage wet pit type structure that can handle axial forces, and the inlet and outlet positions can be arranged according to requirements.

| Q | 90~2700m³/h |

| H | 23~450m |

| T | ≤120℃ |

| N | ≤3000r/min |

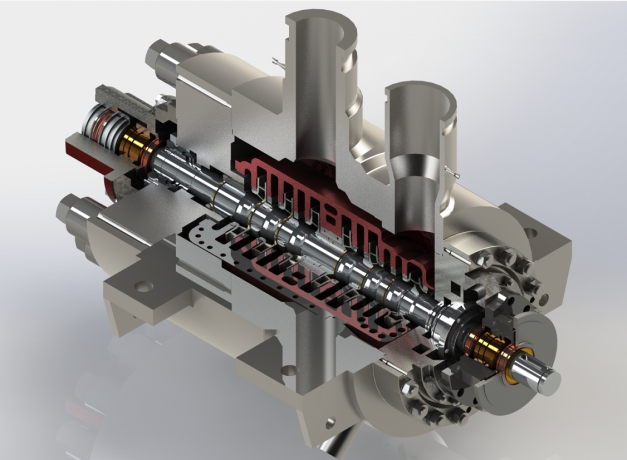

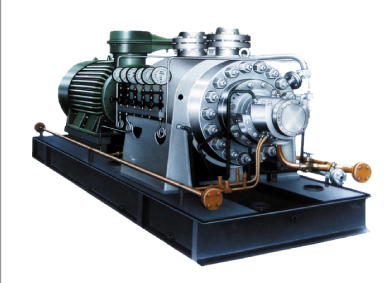

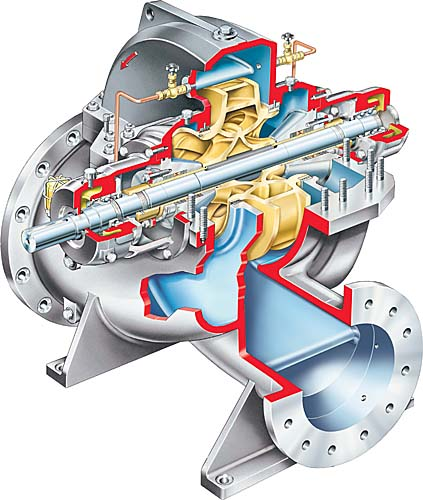

The DG(B) high-pressure boiler feedwater pump has a single-shell, horizontal multi-stage radial split structure. The bearing lubrication can be either self-lubricating or fluid pressure lubrication.

| Q | 6~750m³/h |

| H | 270~2150m |

| T | 150~210℃ |

| N | ≤3000r/min |

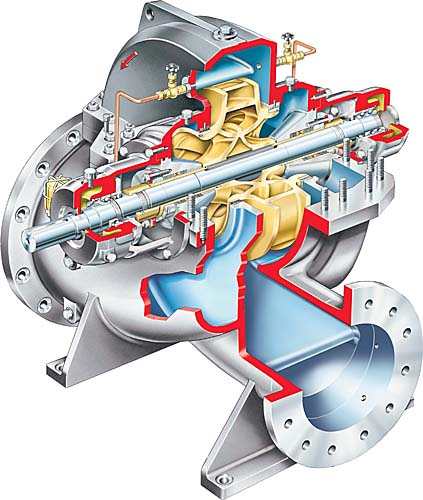

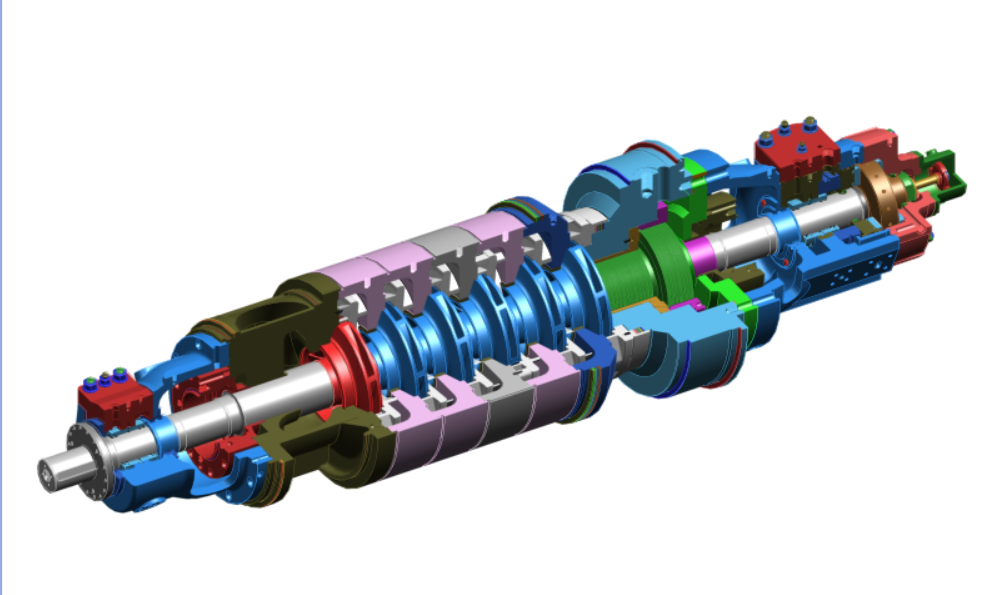

The TDG high-pressure boiler feedwater pump features a double-shell, horizontal multi-stage, and radial split inner casing structure with a semi-extractable core. The bearing lubrication can be either self-lubricating or fluid pressure lubrication.

| Q | 6~750m³/h |

| H | 270~2150m |

| T | 150~210℃ |

| N | ≤3000r/min |

The HDT-Z high-pressure boiler feedwater pump is designed with a double-shell, horizontal multi-stage, and axial split inner casing structure with a fully extractable core. The bearing lubrication is achieved through fluid pressure, and it comes with an inlet equipped with a boost pre-pump.

| Q | 300~2200m³/h |

| H | 800~3600m |

| T | 150~210℃ |

| N | ≤7000r/min |

The HDT-A/C/D high-pressure boiler feedwater pump features a double-shell, horizontal multi-stage, and radial split inner casing structure with a fully extractable core. The bearing lubrication is achieved through fluid pressure, with an inlet equipped with a boost pre-pump.

| Q | 300~2200m³/h |

| H | 800~3600m |

| T | 150~210℃ |

| N | ≤7000r/min |

The H pump can be supported by a single foundation or multiple foundations, and it has a removable pump core with axial thrust supported by the pump body itself.

| Q | 200~60000m³/h |

| H | 6~95m |

| T | ≤90℃ |

| N | ≤3000r/min |

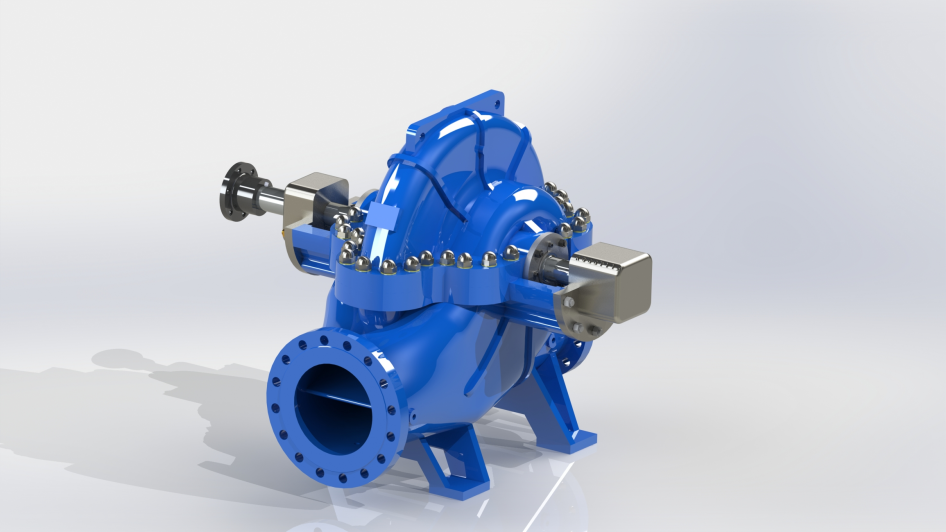

The KSR pump comes with a single-stage double suction or two-stage double suction impeller and a horizontally axial split casing, designed for easy inspection and maintenance. The shaft seal uses packing sealing, and can also use mechanical seals.

| Q | 200~8000m³/h |

| H | 50~200m |

| T | ≤150℃ |

| N | ≤3000r/min |

The SH-type pump impeller is a single-stage, double-suction design, with a horizontally split casing structure, featuring easy maintenance and repair. The shaft seal uses packing sealing, and can also use mechanical seals.

| Q | 200~30000m³/h |

| H | 6~95m |

| T | ≤90℃ |

| N | ≤3000r/min |

本产品适用于火力发电厂150MW~1000M火力发电机组的亚临界、超临界、超超临界高压锅炉给水泵组,用于输送高温除氧、除盐锅炉给水,也可用于工业系统给水系统输送。

HDT型系列泵是卧式双壳体内壳体为径向剖分或轴向剖分高压多级离心泵。泵外壳体和泵盖为锻件结构,外壳体密封面处均堆有奥氏体不锈钢焊层,增强抗高压、高温、高速的流体冲刷和腐蚀。外壳体内部零件采用弹性设计,保证轴承和转子不受温度变化的影响,具有良好的抗热冲击性能。泵的进出口方位一般都垂直向上或向下,泵水平中心支撑。

2.按泵芯结构又分为:

| HDT型锅炉给水泵 | |

|---|---|

| Q | Q=350-2300m3/h |

| H | H=1800-360 |

| T | 100~210℃ |

| N | n≤7000r/min |

| NKN型前置泵 | |

|---|---|

| Q | Q=350-2300m3/h |

| H | |

| T | 100~210℃ |

| N | n≤1480r/min |

本产品适用于火力发电厂中压、次高压、高压火力发电机组配套的锅炉给水泵,用于输送高温除氧、除盐锅炉给水,也可用于工业系统给水系统输送。

本产品为卧式、单壳体、双壳体、单级双吸离心泵。其吸入口水平布置,吐出口垂直向上布置;泵体为中心线水平支撑,在泵筒体的下方设有排液管路、暖泵管路;叶轮和轴采用单级卡环固定结构或过渡配合结构,从驱动端看泵顺时针方向旋转;泵通过两端的滚动轴承来承受整个转子的重量和泵工作时产生的径向力;泵工作时产生的轴向力由双平衡鼓平衡自身轴向力,残余轴向力由非驱动端的角接触球轴承或推力瓦块来承受;轴封采用机械密封,冲洗方式为API682标准的P32、P23;静密封采用缠绕垫和金属面密封;轴伸采用圆锥型轴伸,便于联轴器的拆装,该泵采用稀油自润滑(甩油环)或强制润滑。

2.按泵芯结构又分为:

| 中压 | |

|---|---|

| Q | Q=6~180m3/h |

| H | H=270~600m |

| 次高压 | |

|---|---|

| Q | Q=12~350m3/h |

| H | |

| 高速 | |

|---|---|

| Q | Q=45~ |

| H | |

该系列泵是专为炼油装置中的焦化炉除焦,轧钢厂除鳞用的高压离心泵,亦可供输送其它液体,被输送介质中允许有少量焦质颗粒度<3.0mm,含量小于3000PPm, 介质温度不超过150℃。

设计、制造规范符合美国石油学会API610。

| Q | Q=80~540m3/h |

| H | H=000~3800 |

| 泵壳设计压力 | 最大为42Mpa |

该系列离心油泵主要用于石油炼制、石油化工、化学工业的精炼装置、加氢装置、焦化减粘装置以及石油化工等装置中,输送不含固体颗粒各种油品,渣粘油等易燃易爆、有毒性或腐蚀性的高温高压液体,介质温度不超过450℃.

符合美国石油学会API610标准的规定。

| 中压 | |

|---|---|

| Q | Q=12~540m3/h |

| H | H=560~1000m |

| 壳体承压 | 16Mpa |

| 高压 | |

|---|---|

| Q | Q=25~540m3/h |

| H | H=720~2000m |

| 壳体承压 | 25Mpa |

| 高速 | |

|---|---|

| Q | Q=30 |

| H | H=1500~3200m |

| 壳体承压 | 40Mpa |

The YL series pump can be single-stage or multi-stage and conforms to the VS1、 VS4 or VS6 structural types specified in API610 standards. It utilizes rolling thrust bearings, non-metallic composite material for radial bearings, and self-lubrication for bearing lubrication.

| Q | 6~850m³/h |

| H | 10~300m |

| T | -120~180℃ |

| H | 1485/2990r/min |

The DGB series centrifugal pump features a single-shell, multi-stage segmented between-bearing structure, with the bearing lubrication being either self-lubricating or fluid pressure lubrication.

| Q | 6~750m³/h |

| H | 150~2150m |

| T | 0~210℃ |

| H | ≤3000r/min |

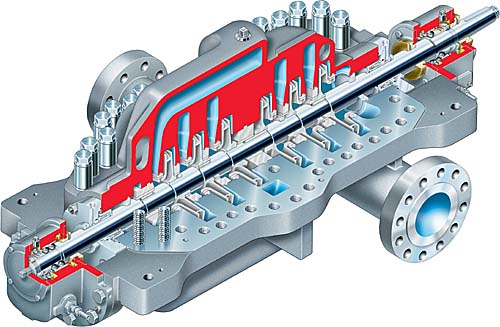

The KDY series pump is a horizontal multi-stage pump with axially split casing, conforming to the BB3 structural type specified in API610 standards. It employs rolling bearings or sliding bearings, with the bearing lubrication being self-lubricating.

| Q | 50~1500m³/h |

| H | 150~1000m |

| T | -20~180℃ |

| H | ≤3000r/min |

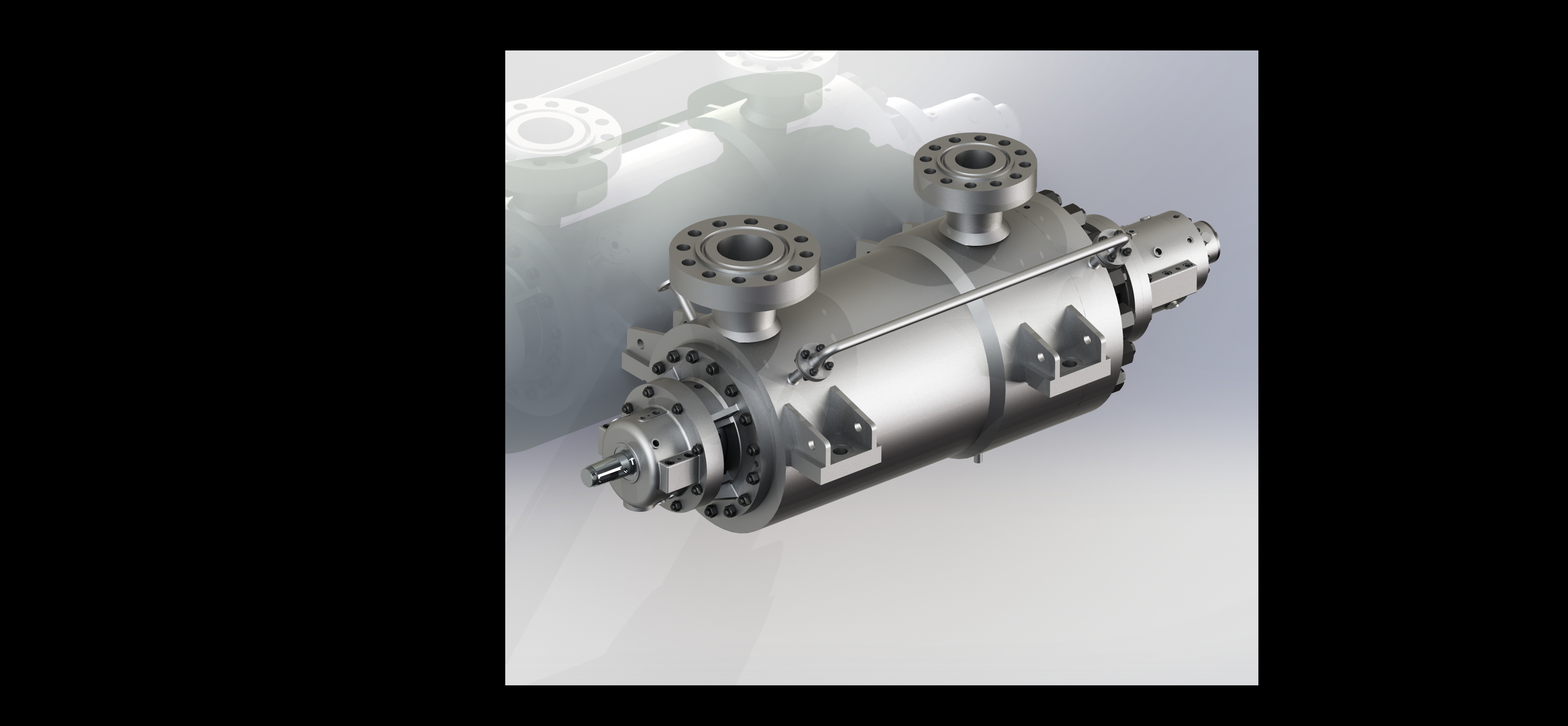

The TD series pump features a double-shell, horizontal multi-stage design with a radial split inner casing, conforming to the BB5 structural type specified in API610 standards. It employs rolling bearings or sliding bearings, with the bearing lubrication being either self-lubricating or fluid pressure lubrication.

| Q | 12~1000m³/h |

| H | 150~4200m |

| T | -20~450℃ |

| H | ≤6000r/min |

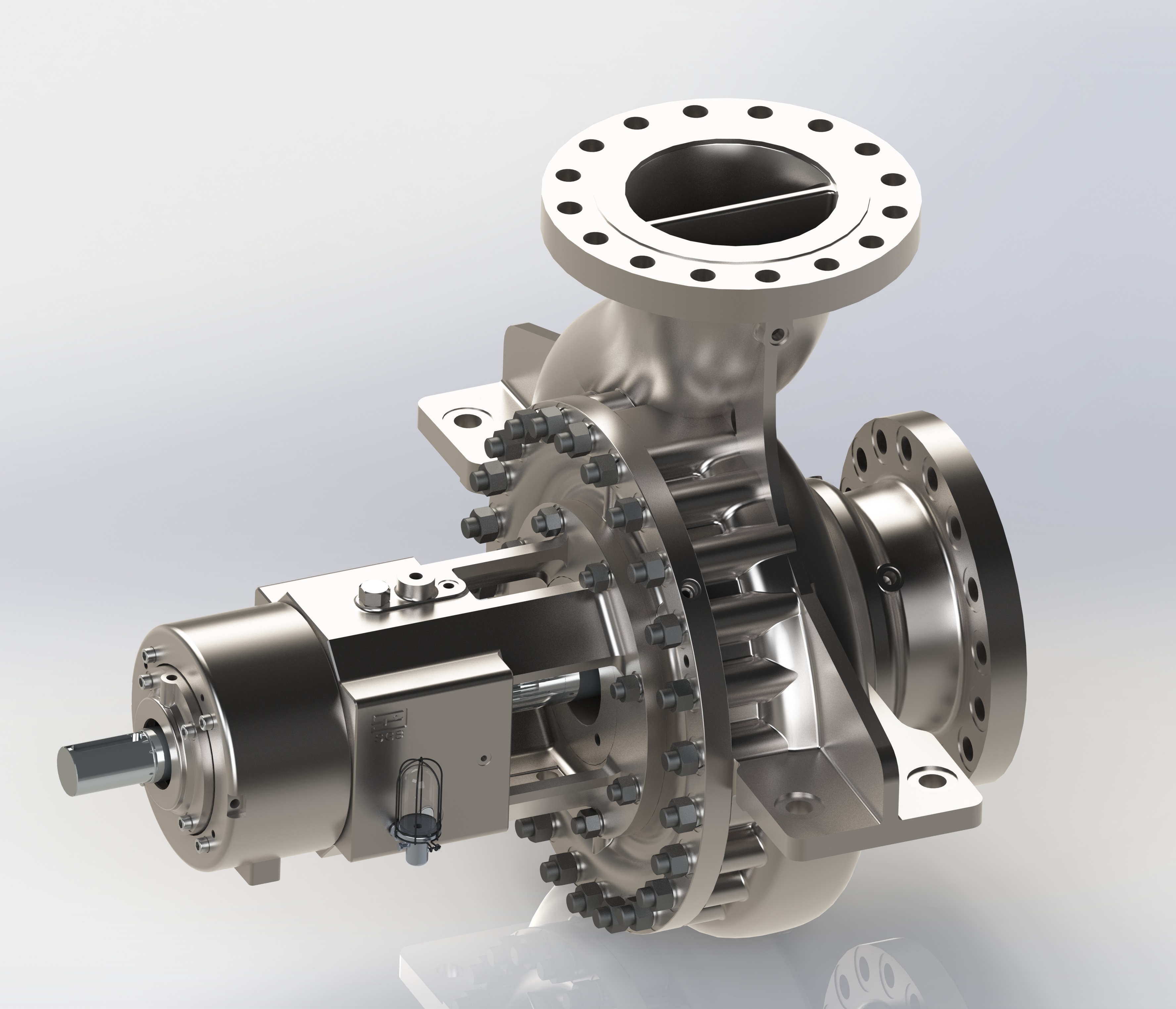

The JH series pump is of a between-bearing design, in compliance with the BB2 structural type specified in API610 standards. It can be single-stage double-suction, two-stage double-suction, or two-stage single-suction. The pump employs rolling bearings or a combination of sliding bearings and rolling bearings, with lubrication achieved through an oil slinger ring, meeting the conditions for oil mist lubrication.

| Q | 12~3600m³/h |

| H | 100~400m |

| T | -40~450℃ |

| H | 1485/2990r/min |

The KSY series pump has a horizontal design, conforming to the BB1 structural type specified in API610 standards. It utilizes rolling bearings or a combination of sliding bearings and rolling bearings, with lubrication accomplished through an oil slinger ring, meeting the conditions for oil mist lubrication.

| Q | 150~15000m³/h |

| H | 30~250m |

| T | -20~180℃ |

| H | ≤3000r/min |

The EH series pump is of a single-stage single-suction cantilever design, in compliance with the OH2 structural type specified in API610 standards. It employs rolling bearings, and the bearing lubrication is achieved through oil slinger ring, meeting the conditions for oil mist lubrication.

| Q | 6~2500m³/h |

| H | 10~260m |

| T | -40~450℃ |

| H | 1485/2990r/min |

1. 产品应用范围:

H型立式斜流泵广泛用于电厂循环冷却水、城市给排水、农业灌溉及其它工业部门输送清水、海水或物理及化学性质类似水的其他液体。其被输送液体的温度不高于55℃。特殊设计水温可大80℃。

2. 泵结构及特点:

H型立式斜流泵结构:1)泵按照安装方式可分为单基础结构和双基础结构。单基础结构泵与电机直连。双基础结构泵与电机分别安装在各自基础上;2)泵的吸入水池为湿坑式,泵直接插入敞开的水坑中,按用户要求也可以设计成干坑式结构;3)泵结构为单壳体结构或双壳体结构。双壳体结构泵水力工作部(包括转子、导叶体、内护管、导流栅等部件)可以同时抽出,方便检修,单壳体结构需整泵抽出;4)泵的轴承为水润滑导轴承。按用户要求可以选用橡胶轴承,赛龙轴承或AR轴承;5)泵轴封,采用填料密封,也可以采用机械密封;6)泵旋转方向从电机向泵看顺时针方向旋转。

H型立式斜流泵特点:1)体积小,重量轻,机组占地面积小,启动前无需灌水;2)安全可靠,使用寿命长;3)效率高,汽蚀性能好。

| Q | Q=600~60000m3/h |

| H | H=6~95m |